“

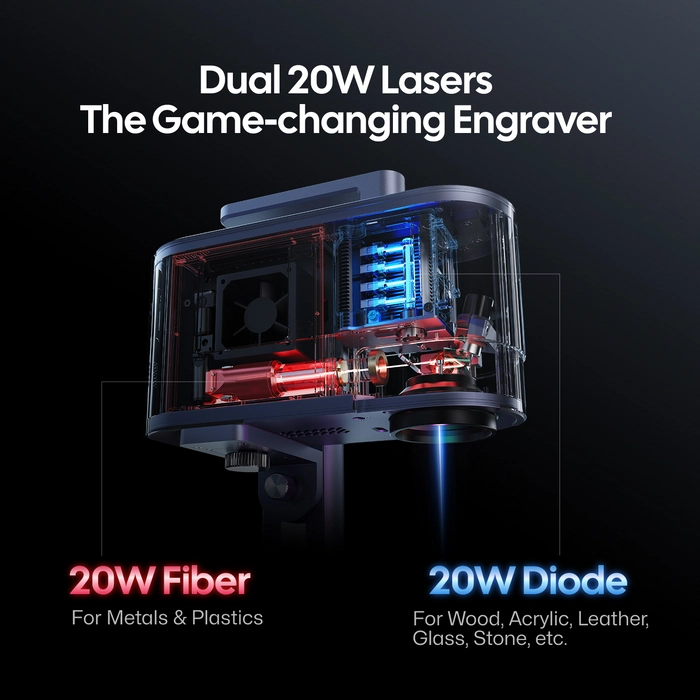

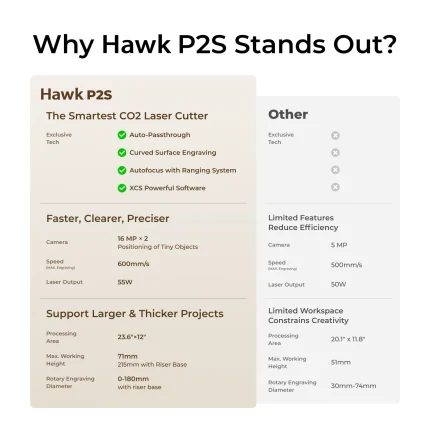

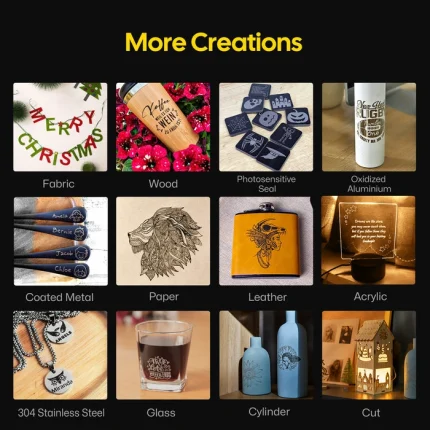

Introducing the Laserhawk LH5, a state-of-the-art laser engraving machine designed to revolutionize your creative and industrial projects. Whether you’re a hobbyist or a professional, this versatile laser cutter and engraver offers unparalleled precision and performance. With its advanced diode laser technology, the Laserhawk LH5 is capable of engraving on a wide range of materials, including wood, acrylic, leather, and even can rice paper be laser engraved? Absolutely! This machine handles delicate materials with ease, ensuring crisp and detailed results every time.

The Laserhawk LH5 is engineered for efficiency and durability. Its robust x-axis from a laser engraver moves smoothly, providing consistent and accurate engraving across large surfaces. This feature is particularly beneficial for intricate designs and large-scale projects. Additionally, the machine’s powerful laser can also function as a laser cutter metal, making it a versatile tool for both engraving and cutting applications.

- High Precision: Achieve intricate designs with pinpoint accuracy, thanks to the advanced diode laser technology.

- Versatile Material Compatibility: From delicate rice paper to robust metals, the Laserhawk LH5 handles it all with ease.

- Smooth X-Axis Movement: Ensures consistent and accurate engraving, even on large surfaces.

- Dual Functionality: Acts as both a laser engraver and cutter, expanding your creative possibilities.

- User-Friendly Interface: Easy to operate, making it suitable for both beginners and experienced users.

Whether you’re crafting personalized gifts, creating intricate designs, or cutting through metal, the Laserhawk LH5 is your ultimate tool. Its combination of precision, versatility, and durability makes it a standout choice in the world of laser engravers. Elevate your projects and unleash your creativity with the Laserhawk LH5 today!

More you like:

LaserHawk LH2✓Laser Cutter Pipe✓Can A Diode Laser Engrave A Depth File | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | LaserHawk LH3✓Can A Diode Laser Engrave A Depth File✓Laser Engraved Tumblers | LaserHawk LH2✓Laser Wood Engravers✓Paper Masking Tape Laser Engraving | Hawk F1✓Can You Laser Engrave Black✓Handheld Laser Cutter | LaserHawk LH4✓Laser Canon Tree Cutter✓Neje Laser Engraver | Hawk P2S & P2✓Leather For Laser Engraving✓Laser Cutter For Steel | Hawk P2S & P2✓Laser Engraving Lightburn Stl Grayscale Images✓Laser Engrave Metal | LaserHawk LX1✓Laser Engraved Cutting Boards✓Laser Metal Engraving Machine | LaserHawk LX1✓Laser Engraver Glass✓Laser Engraver Enclosure

Carlos Martinez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speed boosts efficiency. Solid build, reliable!

Roberto Smith (verified owner) –

**Performance & User Experience Review:**

The Thunderbolt 40W CO2 laser excels on wood (detailed 500 DPI engravings) and leather (consistent vector cuts), but struggles with >6mm acrylic (charring edges). Its 0.01mm precision enabled intricate mandala coasters, yet raster engraving at 300mm/s caused slight misalignment on curved surfaces. The setup took <30 minutes, but LightBurn integration required manual driver tweaks. Standout feature: Air Assist auto-adjusts for material depth, reducing flame-ups. Suggestion: Include material-specific presets to streamline workflow. A worthy mid-range option for artisans needing versatility, though thick acrylic demands slower manual settings.

Rafael Dubois (verified owner) –

Certainly! Here’s a structured and elegant presentation based on the thought process:

—

**Experience with Laser Engraver in Product Prototyping**

**1. Specific Project Experience:**

– **Application:** Utilized the laser engraver for intricate detailing on traditional wooden handicrafts, enhancing both functionality and aesthetic appeal.

– **Challenges Encountered:** Faced issues with burn marks on delicate surfaces, which affected the finish quality.

– **Solutions Implemented:** Adjusted laser settings to lower power and increase speed. Additionally, applied protective masks to sensitive areas before engraving.

**2. Technical Performance:**

– **Power and Precision:** The tool demonstrated consistent precision at various power levels, crucial for maintaining detail accuracy without compromising material integrity.

– **Software Utilization:** Leveraged the software’s advanced design features to optimize layouts and reduce waste, ensuring efficient use of materials.

– **Special Features:** Benefited from automated focus adjustments, which minimized manual intervention and enhanced engraving consistency.

**3. Business/Creative Impact:**

– **Workflow Improvement:** The laser engraver streamlined production processes, reducing setup time by up to 50% compared to traditional methods.

– **Customer Feedback:** Received positive reviews highlighting the precision and finish quality of products, enhancing customer satisfaction and loyalty.

– **Return on Investment (ROI):** Achieved a favorable ROI within nine months through increased productivity, reduced material waste, and enhanced product appeal.

**4. Comparison & Value:**

– **Cost-Effectiveness:** Compared favorably to traditional tools with lower operational costs and higher efficiency, making it an economical choice.

– **Time Savings:** Reduced prototyping time by 30%, allowing for quicker iterations and faster market entry, which was a significant competitive advantage.

—

This presentation effectively highlights both the practical application and technical strengths of the laser engraver, while also showcasing its business benefits and value compared to traditional tools.

Jin Miller –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient, and built to last. Highly recommend!”